Services

Bespoke Models

By harnessing knowledge and expertise gained from successful collaborations with OEMs and suppliers across multiple industries, we have developed a number of effective business improvement models to ensure long-term business success. By integrating processes, technologies and data analysis together, we have created specialised model to drive faster improvement and deliver positive change.

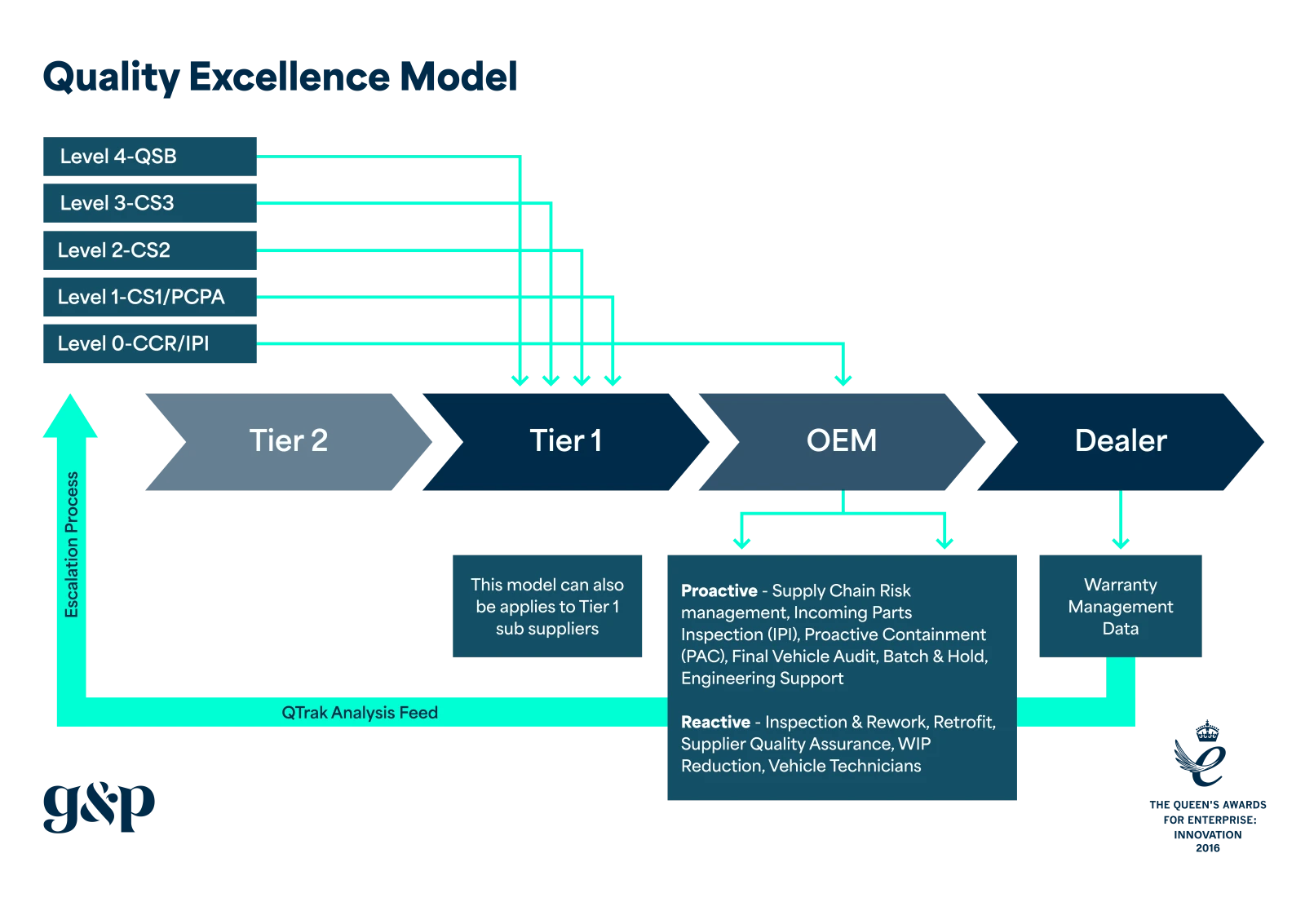

Our award-winning QEM effectively removes disruption from customer facilities, driving intervention up the supply chain, eradicating the root cause and protecting both customer build quality and reputation. This model is underpinned with QTrak, our proprietary project management system that has been designed to meet the specific needs of our services and operations. QTrak not only creates efficiencies and control in project management and reporting but also promotes high levels of data integrity.

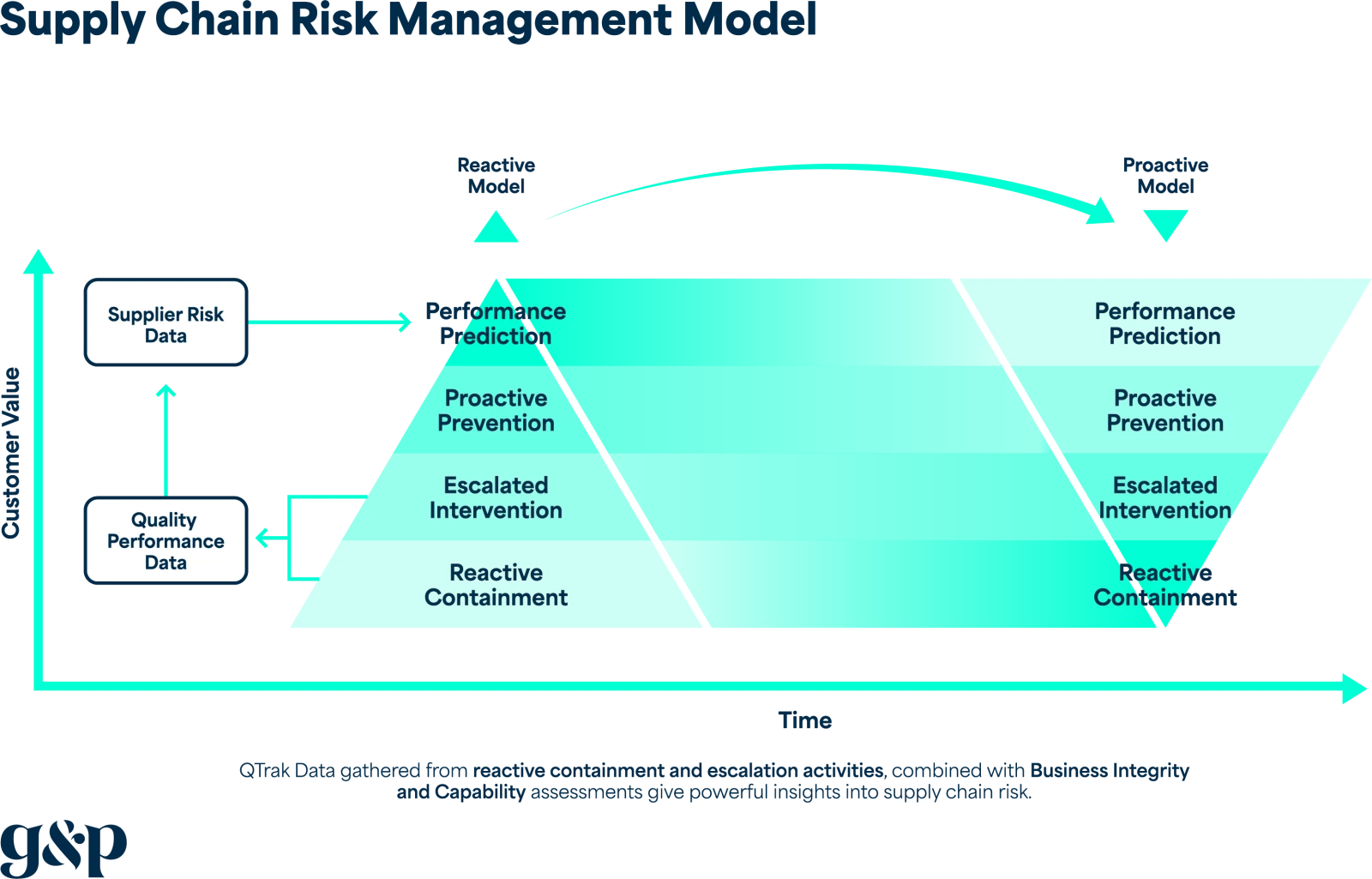

With the ultimate goal of preventing quality issues, rather than simply controlling issues that have already happened, our supply chain risk management model delivers unmatched value. By proactively identifying and then tackling suppliers that pose a higher risk of disruption, we aim to protect the customer from the cost of poor quality by enabling the drive towards zero defects reaching the production line.

Traditionally, we have looked to a supplier’s parts quality performance history as an indicator of the risk presented. However, an immediate downside to this approach is that suppliers without previous issues will not be visible. Instead, we have found that measuring attributes that indicate future performance enhances our ability to predict disruption.

Indeed, by measuring and monitoring both internal and external influences on a supplier’s business integrity and capability, we can build an accurate view of overall performance. When we combine this insight with actual quality performance data, we can forecast the risk level of each supplier and direct necessary resources to those who pose the greatest threat.

A core focus of any OEM or tier 1’s supplier quality team is on the performance of their top 10-15 suppliers. However, due to limited resources, the capacity to review the quality of suppliers further down the supply chain is often unavailable which means risk of a quality incident can go undetected.

By harnessing data to demonstrate the instability of suppliers, identifying key issues and highlighting when proactive action should be taken, we can prevent performance deterioration.

GET IN TOUCH TODAY

Want to improve your business’s quality, efficiency & profitability?

G&P are an international service provider, enabling our clients to benefit from consistent service levels as well as localised points of contact.